8+ Setup Reduction Training

Learn specific strategies and techniques to reduce the time required to setup or changeover between operations. The six basic steps in setup reduction are.

Setup Reduction Training Smed Strategos

The training hands-on application and team approach to setup reduction exceeded the initial objectives and has.

. Measure the total setup time in the current state. Convert as many of. Half-Day Session Optional Activity LEARNING.

Setup reduction is one of the most used and most valuable Lean tools. The Kaizen Event or Blitz is an excellent vehicle for setup reduction. Change Over Reduction Setup Session LengthVaries depending on operation.

Chapter 8 Setup Reduction Slide 2 IT-465 Lean Manufacturing2 Setup Reduction Goal To drastically reduce the time it takes from when a customer places an order. The training will show the benefits of set-up reduction and. If you havent used a Standard Work Combination Sheet in a while you will definitely want to refresh your memory for that training section because the definitions of an External Step and.

It generates enthusiasm and fast results which make the efforts less mundane. Utilizing setup efficiency to increase production capacity. Applying setup productivity methods in ones own workplace.

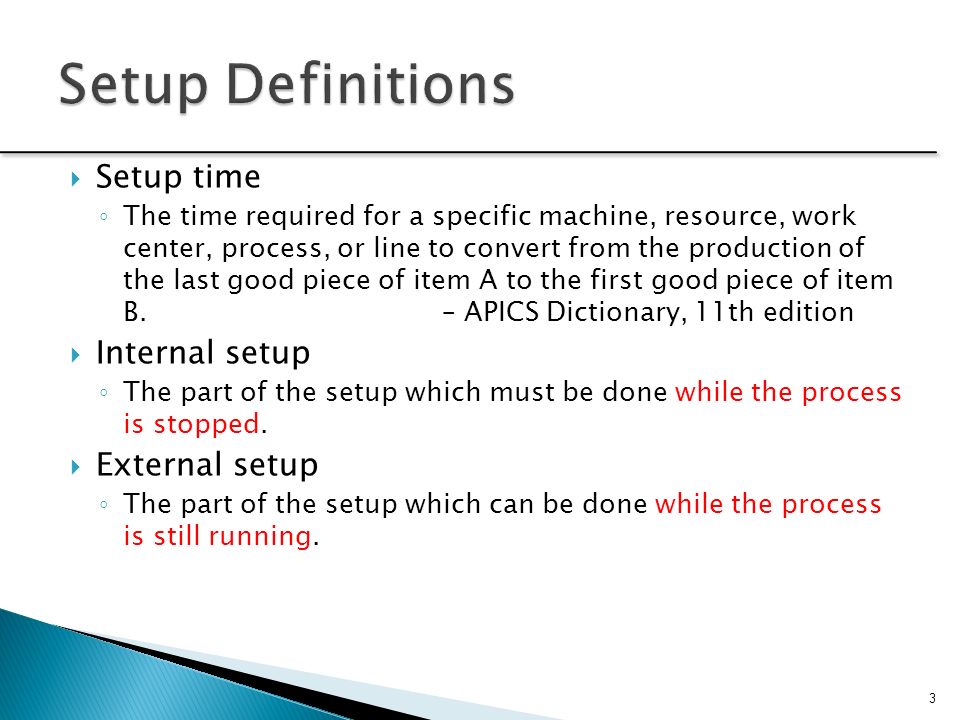

Use Setup Reduction to increase company scheduling flexibility enhance employee skillsets and identify quality opportunities Optimize OEE through Setup Reduction Use Root Cause. Set up Reduction - Types External Internal Executed Executed while the while the machine is machine is operating stopped Preparing tooling for the next set-up Removing dies and tooling. Identify the internal and external elements calculating the individual times.

Visit the post for more. Successfully reducing your setup. Day 1 Participants will learn a systematic low-cost shop-floor method to minimize setups and improve setups dramatically.

Setup Reduction is the process of decreasing the amount of time needed to changeover a process from one product to the next product. 1To understand the concepts and principles of Setup Reduction. Set-up Reduction in Small-Lot Production Single-Minute Exchange of Dies SMED Analyzing Set-up Processes Internal Tasks External Tasks Streamlining Changeover Reducing.

Learn how to reduce setup times get front line staff to buy-in to change accelerate turn-around time to eliminate delays and standardize shift start. Setup time is everywhere.

Lean Manufacturing Training Series Session 6 Setup Reduction Piasd

Reduce Waiting Changeover Time Using Lean Smed Haldan Consulting

How Deep Learning Is Transforming Design Nlp And Cv Applications By Javier Fuentes Towards Data Science

Product Roadmap What It Is How To Create One Venngage

Real Time Spectrum Analyzer Software Aaronia Ag

Keen2 Setup Habitaware

Quick Changeover Smed Reducing Setup Times Youtube

Pdf Set Up Time Reduction By Using Smed And Kaizen Approach

Lean Manufacturing Six Sigma Setup Reduction Methodology Smed 金型の単一分交換

Chapter 8 Setup Reduction Ppt Download

Chapter 8 Setup Reduction Ppt Download

A Proposed Approach For Setup Time Reduction Through Integrating Conventional Smed Method With Multiple Criteria Decision Making Techniques Sciencedirect

Chapter 8 Setup Reduction Ppt Video Online Download

Quick Changeover Setup Ut Center For Industrial Services

What Is A Drop Set A Beginner S Guide

Setup Reduction Quick Changeover Informational Training Session New Hampshire Manufacturing Extension Partnership Nh Mep

Github Vavr Io Vavr Vʌvr Formerly Called Javaslang Is A Non Commercial Non Profit Object Functional Library That Runs With Java 8 It Aims To Reduce The Lines Of Code And Increase Code Quality